- Overview

- Company Profile

Basic Info.

Model NO.

AFC-0516

Gender

Female

Mated Height

2.50 - 9.60mm

Impedance

85-100 Ohms

Circuit

4-24

Housing

Plastic

Terminal Structure

Molded Terminal

Terminal Material

Copper Alloy

Line Spacing

6.35mm

Working Voltage (VAC)

60, 200

Connector System

Board to Board

Product Gender

Male/Female

Brand Name

Afc or OEM

Power Contact

5pin

Signla Contact

16pin

Current Rating

48A

Transport Package

Inner Packing

Specification

58*23mm

Trademark

Anfick

Origin

China

Product Description

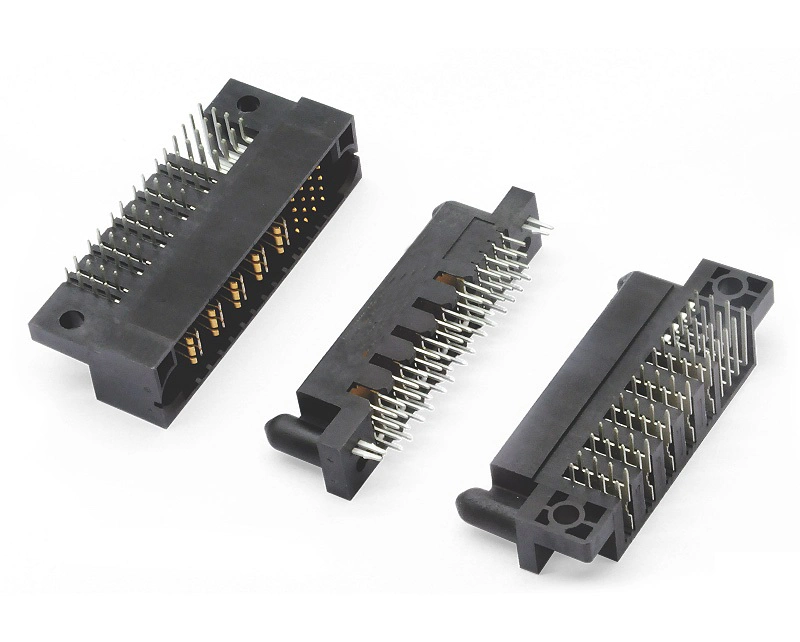

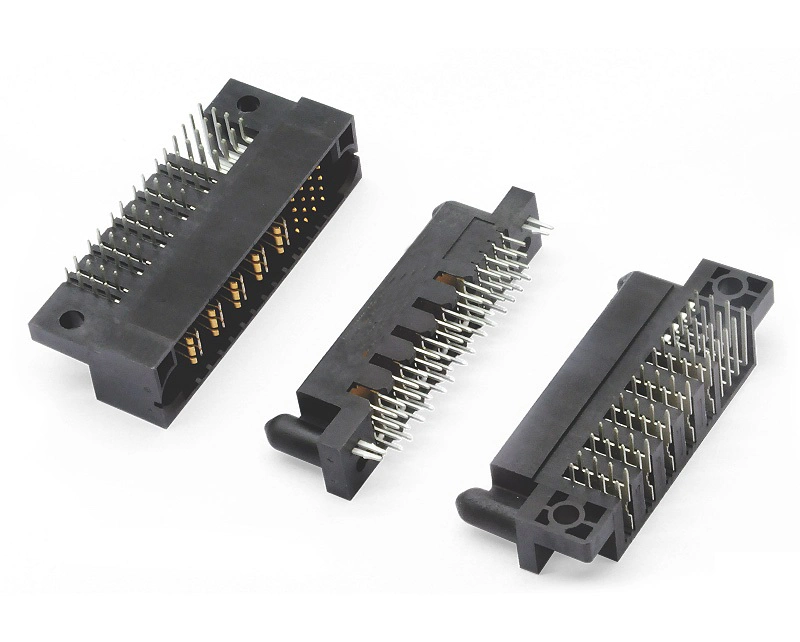

5pin power Mouted blade connector compatible FCI pwrblade connector

Material:

Housing: PPA, glass fiber reinforce,fire rating ul:94V-0, Black

Contact:

Power contact:High conductivity copper alloy,partial or all gold plating

Signal contact:Phosphor bronze,partial or all gold plating

PCB lock: Phosphor bronze, tin plating

| Attribute | Value |

| Component Type | Power Supply Connectors |

| Gender | Male/Female |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 5 |

| Number of Contacts (Signal) | 16 |

| Number of Rows (Power) | 1 |

| Number of Rows (Signal) | 4 |

| Orientation | Right Angle |

| Termination Style | Solder |

| Pitch (Power) | 6.35mm (0.25in) |

| Current Rating | 48A max. for One Powered Contact |

| Resistance (Contact) | Maximum for mated pair is 2m |

| Dielectric Withstanding Voltage | 2500V DC for power |

| Voltage Rating | 250V |

| Color - Housing | Black |

| Operating Temperature Range | -40°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Durability (Mating cycles) | 250 Mating Cycles |

| Solder process | High Temp Solder Process |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Tail Plating (Signal) | 1.98μm (78μin) Tin |

FEATURES & BENEFITS

1. High power contact option (up to 50A/contact; 30°C temperature rise in still air) for cost-effective power

2.Delivery in 1U and 2U power supplies or power distribution applications

3.Low power contact option (up to 40A/contact; 30°C temperature rise in still air) for applications with multiple voltages and lower power requirements

4. Highly vented housing design maximizes heat dissipation for effective system cooling

5. Half-bullet guides offer a reduced connector footprint

6. Large operating temperature range (-40°C to +125°C) for extreme environments

7. Right angle and co-planar options are available with both power contacts for power distribution and signal contacts for power control

8. Number and placement of power and signal contacts are highly configurable for customer's power needs

9. Solder or press-fit tails are available for termination flexibility

10.Compatible with lead-free processing temperatures

TARGET MARKETS/APPLICATIONS

1. AC/DC pluggable power supplies in data, telecom & datacom/networking equipment

2. Industrial PCs

3. Industrial controls & instrumentation

4. Medical equimpent

TECHNICAL INFORMATION MATERIALS

1.Housing : PBTUL94V-0 (High performance thermoplastic PPA+15% glassfiber, UL 94-0)

2. High-temperature thermoplastic (UL 94 V-0), black

3.Power contact base metal

4. High-conductivity copper alloy

5. Contact finish: Separable interface: 30μin. (0.76μm) performance -based plating over nickel Contact A: Phosphor Bronze; Gold plating over Nickel on contact area;Tin Plating on Solder Tail. Contact B: Brass; Gold plating over Nickel on contact area Tin Plating on Solder Tail.

6. Board connector solder tail area: Matte tin over nickel Shell: Brass;Tin Plating on Solder Tail.

ELECTRICAL PERFORMANCE

1. High power current rating: Up to 50A/contact (30°C T-rise in still air)

2. Low power current rating: Up to 40A/contact (30°C T-rise in still air)

3. Operating Voltage • High power contacts: 912V max. (fully loaded) • Low power/signal contacts: 124V max. (fully loaded) • Dielectric withstanding voltage • High power contacts: 2500V • Low power/signal contacts: 1000V

4. Insulation resistance • High/low power contacts: > 2,000MΩ initially as well as after environmental exposure • Signal contacts: > 500MΩ initially as well as after environmental exposure

5. Contact resistance • High power contacts: ≤0.7mΩ initially and after environmental exposure • Low power contacts: ≤1.5mΩ initially and after environmental exposure • Signal contacts: ≤20mΩ initially and after environmental exposure

Environmental Operating Temperature: -45°C to +105°C Power blade connetor blade power connector powerblade connector healthy connector mass health connector wire connector health connector battery terminal connector

Shenzhen Anfick Connector Technology Co.,Ltd ,with more than 40 employees,4 CNC lines,5 assembly lines,we are professional electrionic manufacturing supplier in Shenzhen,China

Anfick covers an area of more than 4000 square meters,we have achieved the ISO9001 :2000,ISO14001 :2015,ROHS,CE,UL,certifications.

Our Connector embly continue to meets and exceeds customer's expectations,such as quality,delivery,service of sales...etc.

Resulting from the corporation culture of honesty,partnership,creativeness,quality excellence,and superior services.

The corporation mission is ' Quality first,Custmomer Satisfaction,Innovation and Advance',in the road of future,Anfick mould connector(ups connector) is committed to our customers' growth and success,more opportunities,more benifits,more reliability.

Our research and development center for UPS(Uninterruptible Power Supply ) ,that most of our engineers have done many years and most work experience,such as intelligent hardware,communications,industrial design.

Our exhibition:

Packing and Shipping:

FAQ:

1. Please be noted that the price in our website is merely the reference price and the actual one is subject to our final confirmation!

2. Any problem, requirement and suggestion, please contact us freely, we'd be very pleased to be at your side.

Q1: Are you a factory or trade company

A:Yes,we are the factory,we have our own connector manufacturer and assembly factory

Q2: How long is your delivery time?

A: Generally it is 3 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q3. How often does your company update the product ?

A: We never ever stop developing new products. We will design a new product according to the market demand.

Q4. Can I place sample order for testing before placing regular order?

A: Yes, trial order is acceptable.

Q5. What payment methods your company accepts?

A: We accept T/T (Bank Transfer), Paypal , Western Union, Cash, L/C etc...

Q6. How about your after-service?

A: We offer 12 months warranty for all products.

About order

Q. Is there a minimum order amount?

A. We don't request MOQ for trial order.

Delivery time:

Q.How about your delivery time?

A: 3 working days after accepting the full payment when the goods in stock.

5-12 working days when the goods out of stock.

Customer Service

Q. What kind of service your company offer?

A:

OEM Service

We can offer our customers OEM service including laser customer's logo on the products

After- service

We promise that we will offer you really after-service, only if our product's issues! Best after-service will be provided by our own professional sales team and after-service team.

Personalized Service

If you have any idea of the products or want to made your special products, welcome dream team! We have our own developing and designing team, which ensure our own technological and innovative products for customers. We will help you realize your dreams.

Transportation Service

We directly cooperate with DHL, you can get goods faster and save your shipping cost.

Other optional express: FedEx,UPS,EMS.

If the quantity is large, we can also transport the goods to you by sea.

We also have other models too if you have interest and you can contact us for more models.

For any more questions or inquiries you might have,please feel free to contact or email us.